By Per Friis Knudsen

Oak barrels is a fun topic and oenophiles (wine enthusiasts) thought it was a good read about basic barrel facts. I believe I could make a lot of articles about why I prefer my gin stored in sherry barrels rather than a wine from a whiskey barrel. Or why a Bloody Shiraz from Four Pillars is my favorite drink on a hot day or after a hard day of traveling, but I will stay on topic and continue within the borders of the wood industry.

Common misunderstanding: Wine and whiskey lovers always compare the age of the spirits instead of the age of the oak staves used in the barrels to store the wine or whiskey. What many people don’t know is that the oak wood is about 3-4 times older that the content. Therefore, I’d suggest that a node of respect is given to the oak barrels next time you sip on an “on the rocks 34-year-old whiskey”.

Oak supply for coopers (barrel makers as mentioned in my last article) was not a problem until the end of the 80’, but the modern growth of the whiskey industry in the 90’ cause the supply to become tighter. An example is that a state law from 2013 defines the label of “Tennessee Whiskey” as whiskey aged in new oak barrels or virgin barrels, which is similar to how bourbon is processed. With 4 years of storage, the need for more and more virgin barrels grew tremendously from 2013 and up until a few years ago. Because if the wood needs to be that good, only the best logs will be good enough and as trees were not grown or planted with intention of making barrels 120 years ago, then the best logs are sold to the highest bidder, which usually is the veneer industry. Whereas a veneer factory would be able to use most of the log for veneer and the rest for other wood component purposes, this study shows that only 22% of the dry wood for making an oak barrel is used for barrel staves and heads.

Only the best is good enough

You can’t just use any kind of quality White Oak to make barrels. It is made from the best White Oak trees available in the forest. The best tree, the best quality, and from the best location. Imagine a barrel stave with a knot, mineral streak, or surface check. I have never seen one. A barrel maker cannot use any kind of defects that compromise the strength of the barrel or the taste of its content. Mineral streaks could potentially pollute a whiskey with an unwanted odor or color. Or surface checks that gives in during storage. As far as I know, not a single defect can be allowed. A barrel that only store 86% of its content is not a good barrel, is it? A barrel needs to be 100% perfect when in use.

I have researched that the White Oak harvest is approximately 20 million m3 per year. About 10% is used for barrels in the bourbon industry alone. The bourbon industry is a $8.6 billion industry in just Kentucky alone. As bourbon is only one of many subtypes of whiskey, it would be easy to assume that the oak barrel industry could face uncertainty because they generally make barrels of logs that are 80-100 years old. Nice tight grain logs in the best quality as mentioned. A good quality wine barrel I have seen cost about $900.

How do we solve this?

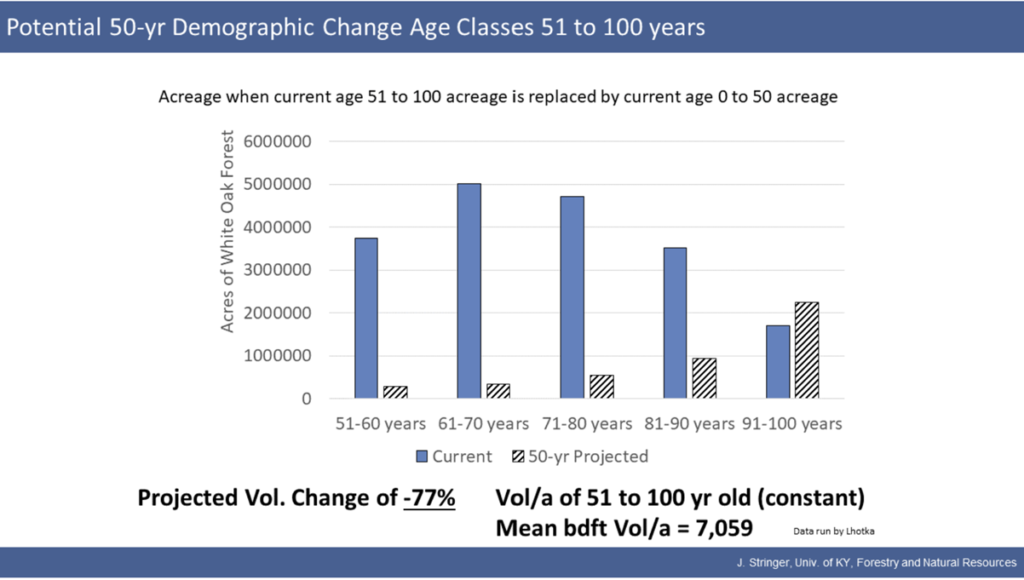

Already back in the 80’, this was a known problem and US coopers was part of the “White Oak Initiative”. This is an organization that has the best interest for the White Oak trees on a sustainable plan and replant more White Oak. They inform that about 75% of all White Oak trees in eastern USA are today classified as mature while the population of young White Oak trees are limited. Therefore, without the intervention of such an organization, the population of American White Oak will start to decline significantly within the next 10-15 years and worsen over the next decades to come.

If initiatives like “The White Oak Initiative” are made in time, we might avoid as steep a decline as feared. They can make sure that we will keep access to White Oak trees for manufacturing of furniture, floors and of cause barrels for many years to come. More specifically, an organization like this actively works towards increasing the volume of White Oak trees in all ages, so we will have plenty of White Oak trees that reaches 80-100 years instead of bringing it into a dangerously low level (graph below).

Another solution might be to look into new developments within the field. Given the decline in the old white oak population, there is an increasing call for the use of wood chips (oak) as an alternative to oak barrels. As barrel ageing is costly and time consuming, use of wood fragments, especially in the form of wood chips, is gaining interest and popularity among wine makers. The use of wood chips has been found to accelerate the ageing process of alcoholic beverages. Also, it is cheaper, eco-friendly, and more sustainable compared to barrel ageing.

Recent studies on the re-use of oak chips for modification of the volatile compounds in alcoholic beverages have shown that you can give different organoleptic characteristics to the beverage by trying different wood concentrations in different temperatures. As you may know, the oak wood used in barrels is subjected to some thermal treatments (toasting in the case of barrel making), leading to the release of those aromatic compounds that give flavor to the drink. Likewise, trying a higher concentration of wood chips at a higher contact temperature gives a prominent woody flavor to the drink. Whilst lower wood concentrations give a fruitier and more floral aroma to the drink. Thus, reuse of oak chips is a feasible alternative to barrel ageing of alcoholic beverages.

Fun fact: American and Irish Whiskey is spelled with an “e”, while Scots is spelled Whisky without an “e” and thereby can be recognized by origin by its spelling. But no rules without exceptions of course.

Other references:

Coelho, E., Teixeira, J.A., Tavares, T., Domingues, L. and Oliveira, J.M., 2021. Reuse of oak chips for modification of the volatile fraction of alcoholic beverages. LWT, 135, p.110046. (https://www.sciencedirect.com/science/article/pii/S0023643820310355?casa_token=q5Knu-Dej8MAAAAA:X0m6kny92-Vv8zx4vyp4wjcwgy0OpgRRav1p5OFtvdAOB05bPwjCXkzzMpXeIrO9zpP-KEN5LWI)

https://www.worldcooperage.com/oak-species-for-cooperage/

Flor, F.J., Leiva, F.J., García, J., Martínez, E., Jiménez, E. and Blanco, J., 2017. Environmental impact of oak barrels production in Qualified Designation of Origin of Rioja. Journal of cleaner production, 167, pp.208-217. ( https://www.sciencedirect.com/science/article/pii/S0959652617319248?casa_token=E99lD-pjNcgAAAAA:OgPje1BBaImtY-g3Bnx141WnikI0ATlgiuj3rr_nB-gDCl8ULAIvFjNMgaFff4W_j2HJwyC6bI4)